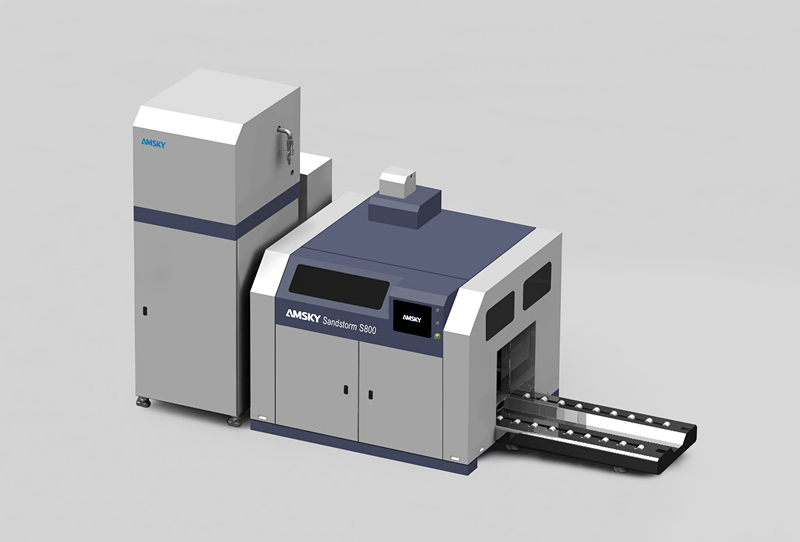

On May 17, AMSKY Sandstorm S800, China’s first sand type 3D printer with self-produced print head, officially made its appearance on the third Metal + Metallurgy China 2018 the 16th China International Casting Expo in Beijing.

As the first domestic brand who owns the piezoelectric ink jet printing technology with independent intellectual property rights, AMSKY always believes that the pursuit and the breakthrough of the leading technology, as well as the technology progress and accumulation, should be the persistence of an industrial technology enterprise.

What makes AMSKY have a strong entrepreneurial gene and what happened during the research and development of AMSKY Sandstorm S800? Today’s “Top Talk” of INTERCONTINENTAL FOUNDRY will interview founder and president of AMSKY Technology Co., Ltd. Li Mingzhi. Let’s look for the answer in the conversation.

Li Mingzhi

Li Mingzhi, founder and president of AMSKY, and national hi-tech industry leader. AMSKY he founded focuses on the research and development of industrialization printing core technology and commits to providing solutions of industrialization printing core technology in the applications fields and complete sets of devices. On July 5, 2016, AMSKY was officially listed on GEM.

INTERCONTINENTAL FOUNDRY: First of all, thank President Li Mingzhi very much for your time to accept our “Top Talk” interview of INTERCONTINENTAL FOUNDRY. We have just witnessed the official appearance of AMSKY Sandstorm S800 at the exhibition site. When did you and your team start to develop Sandstorm S800?

Li Mingzhi: Sandstorm S800 is a professional industrial 3D printing device which is initialed in 2012. The device we started is very complex in the printing field. Before our device was introduced, almost all the 3D printing device on the market are imported from abroad, mainly from the United States and Japan. I remembered that the price of an imported 3D printing device at that time was in the seven-digit (million) range, very expensive. And 3D printing technology is an indispensable part in the future industrial casting field. Therefore, we decided to develop the device with independent intellectual property rights to replace the imported device, thus reducing the price of 3D printing. Let more Chinese foundry enterprises have the opportunity and the ability to embrace the new technology of the industry.

I.F.: Any excellent device, from R&D to production, can’t be separated from the support of technology. I wanna ask how many manpower and material resources have been invested in the R&D and production of Sandstorm S800.

Li: That’s true. As the first domestic brand who masters piezoelectric inkjet printing technology with proprietary intellectual property rights, AMSKY, in the research and development of Sandstorm S800, has always been pursuing the leading technology breakthrough. We believe that only by continuous progress and advanced technology accumulation, can technology enterprise bloom strong vitality. What’s more, in terms of technology research and development, AMSKY has reached close cooperation with famous domestic universities such as Peking University, Zhejiang University, Zhejiang University of Technology and Hebei University of Technology in many fields. Thanks to the efforts and cooperation. Sandstorm S800 successfully makes its debut today.

I.F.: When it comes to the hi-tech product and technology, many people may feel that the foreign products are more advanced. So as the industrial 3D printing device with proprietary intellectual property rights, how is Sandstorm S800, comparing to the products and devices from famous international manufacturers?

Li: In terms of printing technology, Chinese technology and any foreign enterprises are neck and neck in the field of industrial 3D printing. Since the first commercial 3D printer developed by American in 1986, the world has begun to compete for 3D printing technology. Although 3D technology starts late in China, the speed of development is obvious to all.

Let’s take the Sandstorm S800 we just released as an example. By adopting self-developed inkjet print head, the print resolution of the sand type 3D printer can reach up to 600dpi and the build speed per single layer is 25 second/layer, which is much higher than the same products from home and abroad. What’s more, our Sandstorm S800 can control the actual deviation within ±0.3mm in printing accuracy. However, we should also be aware of the fact that, although our 3D printing technology and device are on the global leading edge, there is still a certain gap between the domestic enterprises and famous international enterprises in the aspect of 3D printing consumables. Therefore, the industrial 3D still has a long way to go in China. But we believe that China's global dominance in industrial 3D printing is around the corner.

I.F.: Is the 25 S/layer build speed in Sandstorm S800 you mentioned fast in the 3D printing industry?

Li: This speed in industrial 3D printing field is a little bit faster than normal, but is much faster than traditional sand casting. On the one hand, the trigger time is shorter than traditional craft process; on the other hand, the printing efficiency is really fast. However, 3D printing technology is still developing and maturing rapidly. Before long, AMSKY will introduce bigger, faster, and more efficient 3D printing device.

I.F.: On CCTV's “Big Country, Heavy Equipment”, we saw that 3D printer in Ningxia are used by one company to produce casting sand cores. So as far as you know, is China's industrial 3D printing popular now?

Li: Unfortunately, as far as I know, the popularity of industrial 3D printing in casting industry is not too high. There are two important reasons: one is that casting industry is still a traditional technical industry whose attributes leads to a longer cycle of technical innovation; the second is the previous 3D printing technologies have greater improvement room in printing speed, precision, dimension and price of printed parts. At present, casting enterprises are in a difficult transition period. After “Made in China 2025” released, it is indisputable that advanced productivity has replaced backward production technology. We believe that there will be more and more enterprises starting to use AMSKY Sandstorm S800 for production.

I.F.: At present, casting industry is facing the high-pressure supervision from environmental protection policy, and many enterprises start to seek more environmental protection technology for production. So does industrial 3D printing technology meet the environmental standard and what advantages does AMSKY Sandstorm S800 have?

Li: Firstly, 3D printing technology is a new technology that meets the demand of our environmental policy. Comparing with traditional casting craft, 3D printing has the advantage of reuse of raw material. This is the most prominent environmental highlight.

Sandstorm S800 3D printer, for example, can reuse more than 80% of sand raw material, which is almost impossible in other casting industrial crafts. Over 80% raw material reuse, on the one hand, can relieve the dependence and needs on natural resource; on the other hand, effectively reduce the purchase budget of consumables, raw and auxiliary materials. So 3D printing is environment friendly, and achieves cost reduction and efficiency increasing in casting industry.

I.F.: Someone once told us that 3D printing technology was only used for small volume casting, not suitable for mass production. Is that really the case?

Li: In the past, due to the limit of technology, 3D printing technology did face many challenges. But after so many years of development, 3D printing technology has been tended to mature in both speed and print dimension. Like our Sandstorm S800, the maximum print dimension can reach up to 0.9×0.6×0.4m, which can satisfy the common sand type casting. But simple saying that "3D printing is not suitable for mass production" doesn't make much sense. For industrial 3D printing, the most outstanding performance is to produce the high-end and precise products. At present, the parts and components produced by casting industry are more and more complex and accurate. In this aspect, our traditional craft must keep pace with the changes in the market. As I mentioned above, AMSKY Sandstorm S800 can control the error within ±0.3mm, which can bring a lot of convenience to enterprises for producing high-precision and complex products and improve enterprise efficiency.

I.F.: We also wanna know that is the technical threshold very high for the enterprises who want to layout 3D printing?

Li: Firstly, industrial 3D printing is a digital bias technology, which actually has a technical threshold, but in this rapidly changing society, who can guarantee that their products can all win without new knowledge. Secondly, many people tend to overestimate the technical threshold of 3D printing. In fact, the world is full of casting companies operating in 3D printing, which shows that it is very easy to master3D printing technology. For a 3D printing enterprise, the most critical part is digital modeling. This is somewhat similar to traditional sand casting. In the past, companies used to cast molds before making parts. And as same, before 3D printer starts production, engineers needs to make the digital model of product by computer. So if an enterprise wants to get into 3D printing device, the most necessary thing is to have an engineer who is proficient in digital modeling.

There is an old saying in China that “It is better to teach a man to fish than to give him fish.”

Besides research and development of product, AMSKY also makes our own contributions on promoting industrial 3D printing technology, actively accessing various enterprises and providing technical guidance to the backbone of the enterprise to rapidly master the 3D printing technology. At the same time, we will also provide long-term technical support to these enterprises. Whenever the enterprise encounters production difficulties, we will help solve them as soon as possible.

I.F.: Next, what surprises will AMSKY bring to casting industry in 3D printing field?

Li: First of all, we will increase the investment, developing more advanced 3D printing technology and devices. Within a year, we are expected to introduce S2000 and S4000 whose build speed is much faster and print dimension is much larger. With the features of ONEPASS uninterrupted printing, Sandstorm S4000 can achieve 18s/layer build speed and maximum 4m×2m×1.2m printing dimension, satisfying the production needs of more enterprises.

I.F.:After years of development in China industrial 3D printing, what do you think is the greatest change in China’s casting industry?

Li: I have a friend who is doing big data analysis in Alibaba. He once shared a sentence with me, which shocked me. He said that the past ten years had made many internet companies successful and in the next five to ten years, there would be a large number of advanced manufacturing companies and giants. These manufacturing companies are the footstone of our entire economy in China, and only with these companies, can we make more systematic transcendence.

Recently we visited many enterprises, entrepreneurs and innovators. They are successful in their own fields. What they need in the current stage is to come together and to set a very specific target. I believe, with the support of capital platform, we will stand on the peak of international level manufacturing industry with a new attitude.

Finally, I wish Chinese advanced manufacture can become world’s advanced manufacture!

Link: AMSKY Sandstorm S800 caused a heated discussion.

On May 17, AMSKY Sandstorm S800, the first domestic sand type 3D printer with self-produced print head, unveiled by AMSKY on the third Metal + Metallurgy China Expo 2018, caused a heated discussion in the industry.

Yang Weidong, professor of Hebei University of Technology, D.E (doctor of engineer), and master tutor, expert member of Ministry of Industry and Information Technology of the People ’s Republic of China in the additive manufacture field and vice director of China 3D Printing Technology Industry Alliance, said that as the first domestic sand type 3D printer with self-produced print head, AMSKY Sandstorm S800 had the overturning and revolutionary significance in the 3D printing industry at home and even around the world.

Liu Jinhai, professor of Hebei University of Technology, executive deputy director & secretary-general of Tianjin Foundry Association and iron casting technology committee of National Foundry Society, indicated that the Sandstorm S800 broke up the technical barrier and made the piezoelectric inkjet print head technology of 3D printing industry no longer be subject to foreign countries, which was a very memorable event.