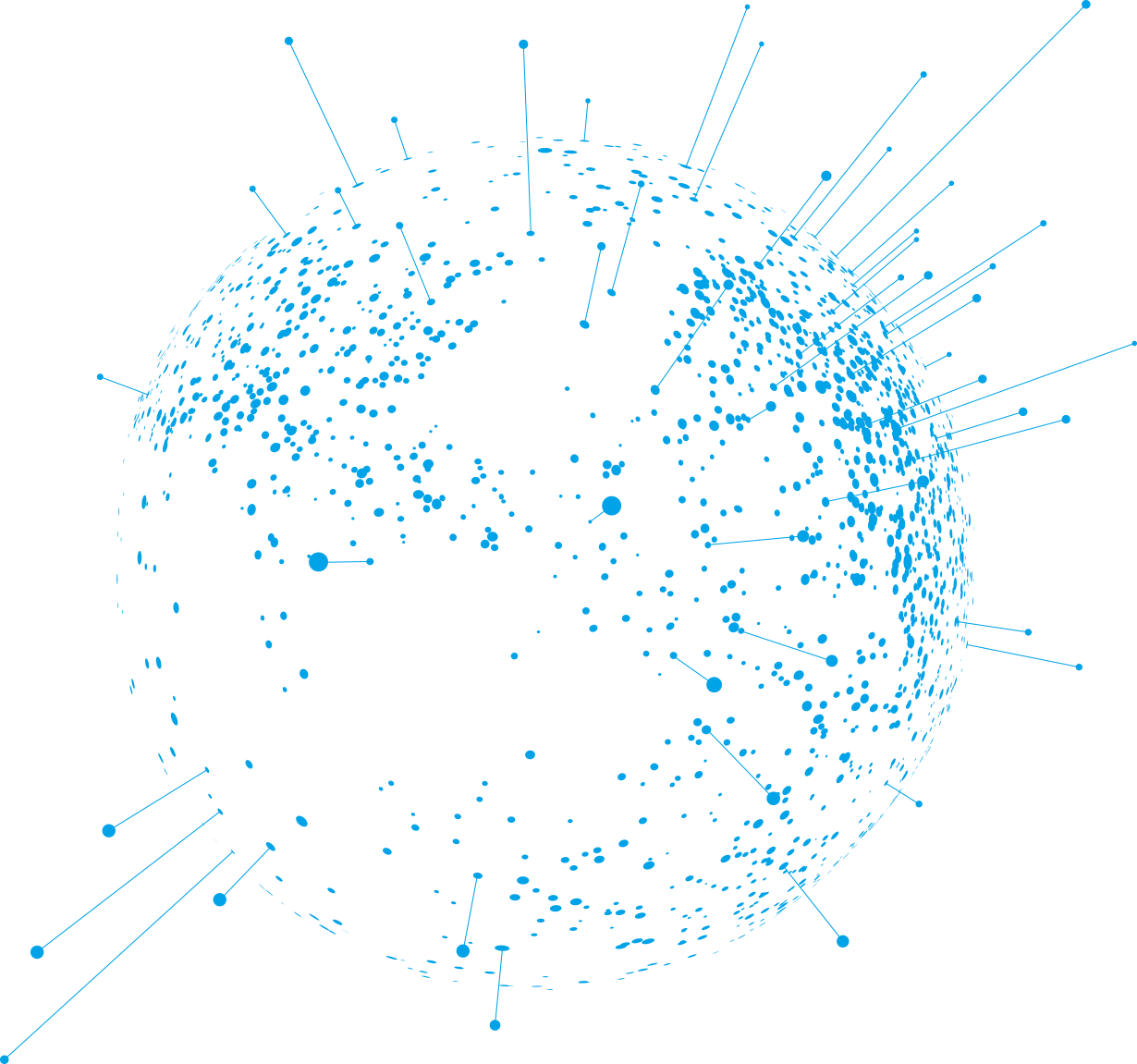

On April 9th, 2019, 9:00 a.m., the 4th International Printing Technology Exhibition of China (Guangdong) or Print China 2019 was grandly opened at Guangdong Modern International Exhibition Center. AMSKY, as well-known enterprise in global CTP (Computer-to-Plate) industry, actively involved himself in this exhibition and presented the latest 256-channel laser CTP-Aurora 256-8 to the attendees.

▲AMSKY's booth at Print China 2019

As the most state-of-the-art product among CTPs of AMSKY, Aurora 256-8 CTP breaks through the limitation of conventional optical fiber with the adoption of 256-channel spatial light modulator independently developed by AMSKY, which realizes output speed at twice the rate and fineness and precision of image at tenth the rate of the original. Now let’s have a look at the technical merits of Aurora 256-8.

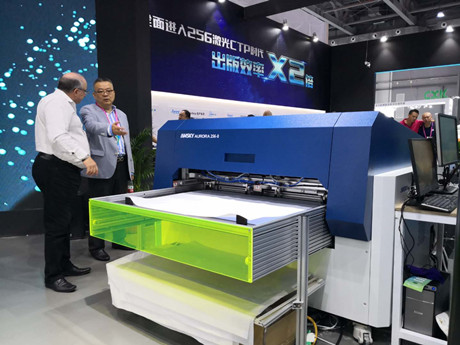

1.Output speed x2

With AMSKY 256-channel spatial light modulator, Aurora 256-8, getting rid of the energy attenuation caused by the transmission of traditional optical fiber, makes breakthrough on the drum speed , achieving 35-55plates/hour for 8-up plates, two times faster than the former devices.

▲256-channel laser technology: four times more efficient than conventional optical couple technology

2.Saturation increasing by 21% and fineness and precision at tenth rate of the former with the adoption of square screen imaging technology

In stark contrast to the conventional circular screen, the square screen generated by AMSKY 256-channel spatial light modulator makes the edge of image more sharp and clear and dot distribution more even. The saturation is increased by 21%. Moreover, the energy distribution of the rectangle and step-like square screen being no longer limited by the optical fiber, perfectly realize FM screening, over 10 times more accurate than 200lpi AM screening.

▲More sharp and clear image edge under square screen

3.Less replacement and maintenance, lower energy consumption and cost

Only one laser is used as the laser source, rather than fiber and other valuable parts adopted, reducing the cost of replacement and maintenance. Thanks to the rapid plate making and lower energy consumption of drum speed, only approximately one degree of electricity is needed to output 13 pieces of 8-up plates, over two times less power saving than conventional plate making.

4.High-precision positioning of linear motor, longer service life

The linear motor with Nano-level, on account of the elimination of all kinds of positioning deviations caused by intermediate links, boasts high-precision positioning. No-contact rotation can be achieved. Except for the loss of guide rail, almost no mechanical friction loss is generated, less failure and longer service life.

5.Tailor made for customer

Full-automatic alignment/punching function (not limited by the size deviation of the plate, and the reference edge if strictly aligned), interleaf paper recycling system, optical imaging system, single cassette, and multi-cassette are available for customers.