The four-yearly German International Foundry Exhibition (GIFA 2019) will be held in Dusseldorf, Germany from Tuesday, June 25 to Saturday, June 29, 2019. AMSKY will attend the grand gathering with our 3D Print Team for deeper interaction with the mold industry, further offering more services to the whole mold industry and enterprises with 3D printing technology and service. We sincerely invite you to visit our booth for communication and guidance.

Exhibition: GIFA 2019

Data: Jun. 25-29, 2019

Location: Dusseldorf Exhibition Center in Germany

Booth: 14A52-04

▲Design of AMSKY booth

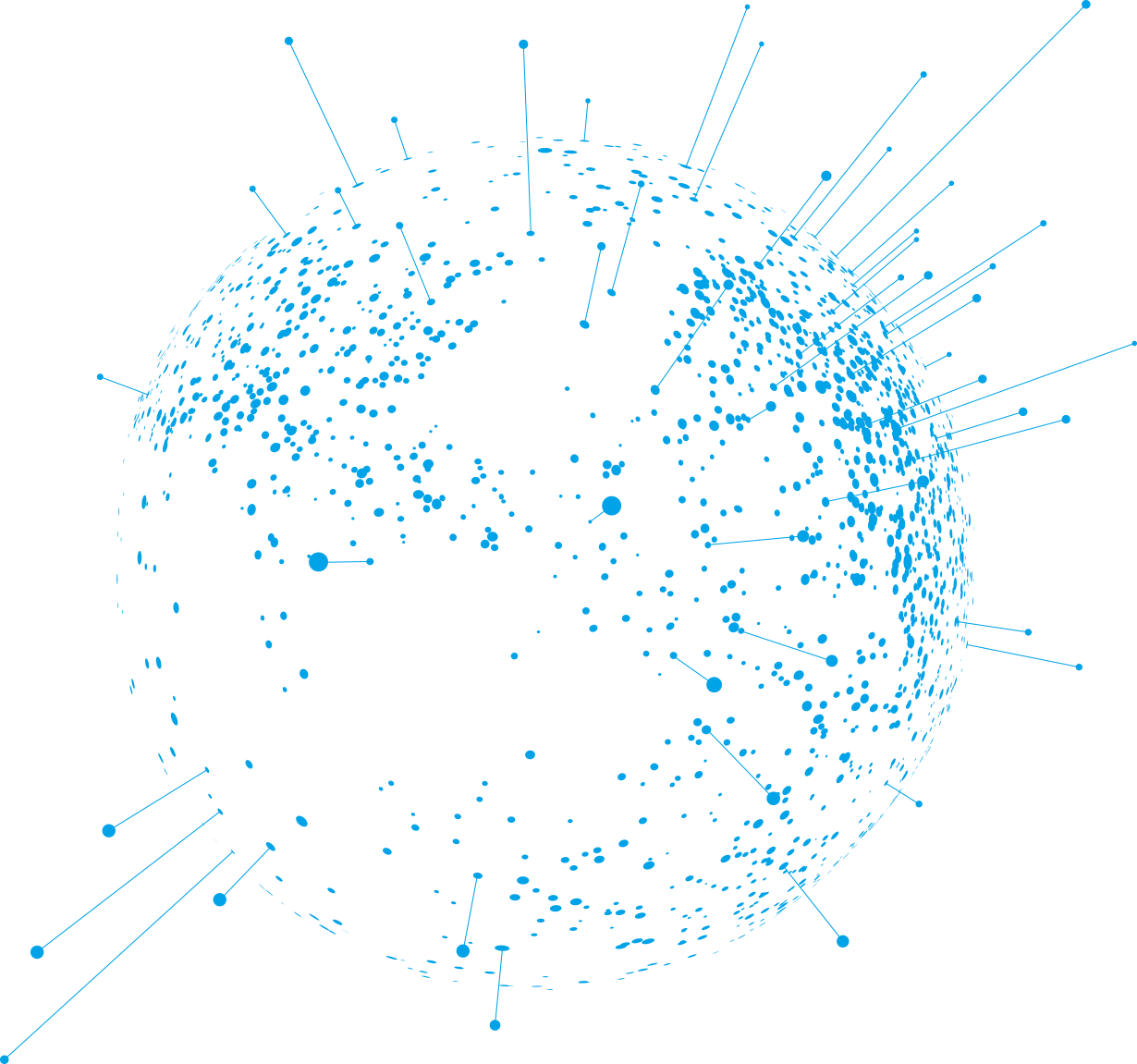

In this exhibition, our AMSKY team will mainly introduce AMSKY Sandstorm S2000- the sand mold 3D printer specialized in most commercial sand mold printing and with core technology self-developed.

▲AMSKY Sandstorm S2000 3D printer

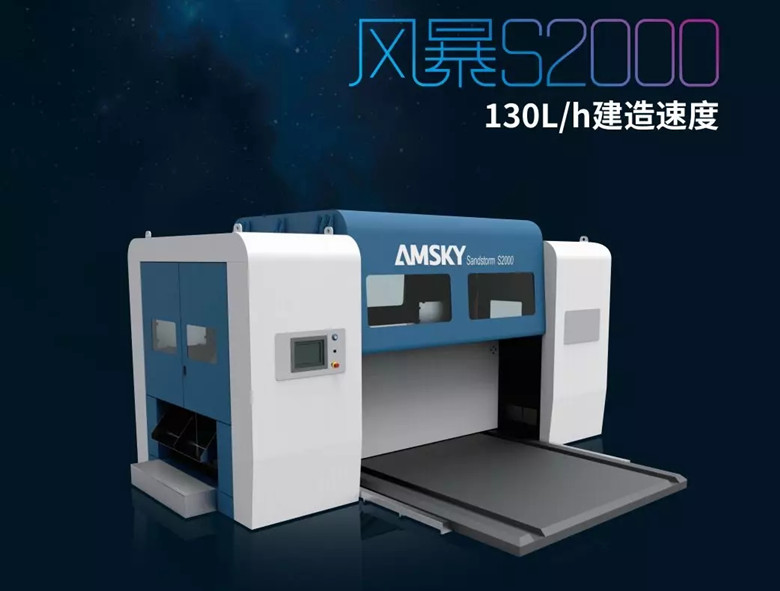

▲AMSKY Sandstorm S2000 3D printer

▲AMSKY Sandstorm S2000 3D printer

Six advantages of AMSKY Sandstorm S2000 3D printer:

· 130L/h build speed (for 0.3mm layer)

With 95-130L/h build speed, the time for printing one job box can be controlled within 12-14.5hours, meanwhile, the deviation can be within ±0.3mm when product precision is smaller than or equal to 400mm and 0.1mm when larger than 400mm. The performance achieves the top level of international sand type 3D printer, and the sanding speed is higher than any product of the same model.

· ±3μm

With the combination of linear motor and raster ruler, the volume is reduced and the working reliability, speed and precision are improved with 1um precision of the raster ruler.

· Cast iron frame

With cast iron frame, the reliability and stability is raised to a new level, meeting the general requirements of machine tool level.

· Double job boxes, working 24 hours a day

The standard double job boxes accomplish one job box is still clearing sand while another has already been printing, continuous working 24hours a day.

· Full-automatic sand pre-treatment

The fresh sand firstly being loaded into the sand bank, the subsequent process, instead of manual sand mixture and feeding, will be automatic finished without annual intervention.

· Tailor-made for customer

In responding to the different printing needs, the quantity of print head, resolution, and size of ink drops can be tailor-made according to requirement of customer.